|

HISTORY

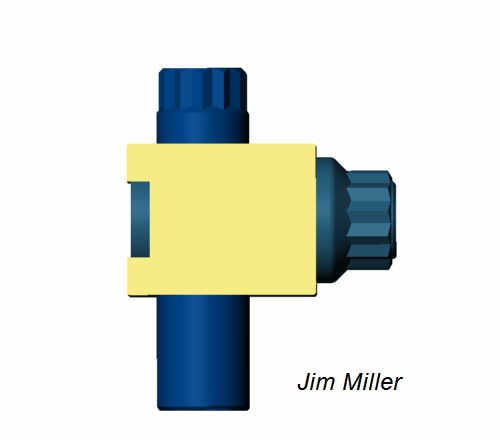

STUD-BRIDGE™

DISCONTINUED

The Patented Miller STUD-BRIDGE™

revolutionized the concept of what a "stud girdle" was intended for: securing

the rocker arm mounting studs from flex! One look at the innovation shows what individual

locking bolts can do, compared to the sandwich style gripping of smaller bolts

across two bars, typical of the traditional stud girdle designs.

DISCONTINUED

|

|

|

The Patented 1/2" dia. T-Bolts

and 12-Point Nuts are made of 8740 Chromoly Steel, heat treated for 200,000 psi,

with hardened washers. Their half moon cutaway overlaps an extended length,

precision ground .608" diameter, 12-Point Adjusting Nut for SOLID steel on steel

locking - one on one! Conventional stud-girdles have a single 3/8" bolt

straddled between 2 or 4 adjusters, compressing their clamping force. MEI's

STUD-BRIDGE™ is all

TENSILE. The 1.00" x 1.25" STUD BAR is slim and trim, one piece, and made of

7075-T6; precision machined within .001" tolerances. No set screws are needed to

keep lash from moving, and a great benefit of the

STUD-BRIDGE™

is that

it ALIGNS the rocker mounting studs in perfect parallel to the valve stem,

keeping side flex during operation to NOTHING. (See:

ROCKER MOUNTING)

The

STUD-BRIDGE™ can be mounted so the

1/2" 12-Point Locking Nuts can be placed on either side, for your convenience

in engine tuning or valve train maintenance.

MILLER MID-LIFT™

The Standard By Which All Is Measured!™

954-978-2171 MillerRockers@aol.com

MID-LIFT™, PRO-SHAFT™ & PRO-STUD™ are JM Miller Trademarks; Copyright © MMIII~MMXXIV

| |