|

|||||||||||||||||

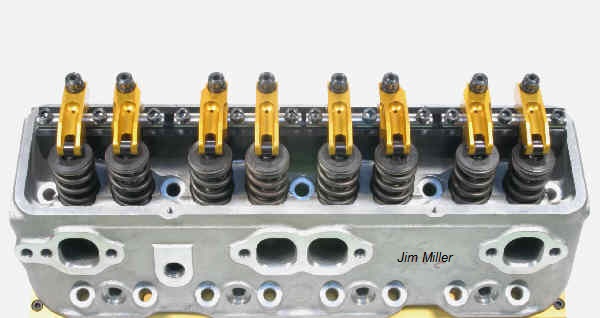

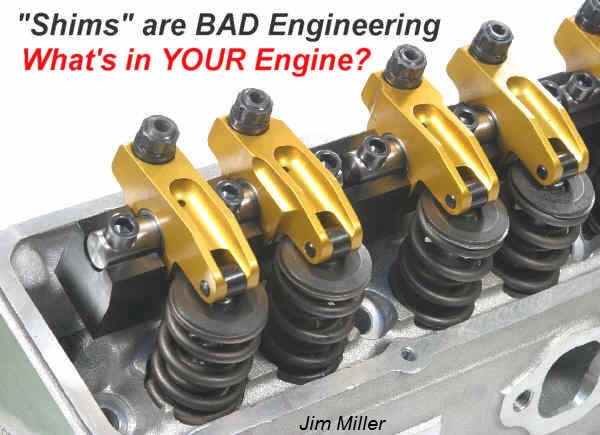

® Geometry from the principles of precision rocker arm engineering we developed in 1973 and Patented in 1982; and was later endorsed by both Chevrolet and Chrysler’s racing engineers. No other company can claim this. 2. The rocker bodies are fully CNC machined (on 100% of all surfaces) by MEI’s 4-Axis Kitamura high speed machining centers, from a solid block of Alcoa’s proprietary 7150 alloy; the same material used to make the Boeing 777! This technique allows the molecular grain to run "lengthwise" with the rocker body, making fatigue resistance 6 times higher than the "cross-grain silhouette extrusions" used by the other two #1 "shaft" rocker manufacturers. 3. Twin-rib rocker beam with ball mill lightening, and drip down oiling are but only two design features first introduced on the Miller BOSS 429 rockers in 1980, that continue to this day, providing the greatest strength flowing up from the load points imposed over the 8620 precision ground roller pin and honed roller tip, while yielding the lightest in moment-of-inertia dynamics. Full compliment Universal Bearings, Torrington Thrust washers and MEI’s 7/16-20 Form Rolled J-Thread Adjusters and 12-Point nuts finish out the ultimate combination of engineering, materials and workmanship available. 4. The full length STANDS are made from solid billet 7075-T6 bar stock, precision machined to specific head applications; using high strength precision formed, Rolled J-Threads to retain the shafts. 5. Each PRO-STAND™ system is Serial Numbered and traceable for all specification records. 6. ARP/Jim Miller 7/16" 12-Point Crown Mounting Bolts secure the stands to the heads with shallow counter-bores for maximum material; while rocker shafts are secured by Grade-8 cap screws. 7. MPG ROCKER SHAFTS are made from 8620 aircraft grade steel, fully machined on state-of-the-art 5-Axis CNC Mori-Seiki bar feed turning center, then precision centerless ground finished. NOTE: We DO NOT endorse the use of "shims." Shims are BAD ENGINEERING, and we strongly recommend against them. Miller PRO-STAND™ systems are provided with a SURPLUS of material which requires the bottom of the stands to be cut for proper Installed Geometry by the engine builder. Removing anywhere from .100" to .300" may be needed, but most applications are closer to .200". The exact amount will depend on your engine’s particular combination. SUMMARY

| |||||||||||||||||