|

SERIES II,

1977

|

The original Series I rockers of 1973

were essentially unchanged when the Series II rockers were made 4 years later.

The only difference was that they incorporated Torrington Needle bearings, where

the Series I used a bronze bearing to work with the Ford .700" diameter NASCAR

shaft. Only 5 sets were made; four of these were used

solely on Jim's own BOSS engines. Although it was 4 years after the first Series

1 rockers were made before the Series II came out, they were in the pipeline

long before that, so there was no urgency to make more of the Series I rockers.

|

|

|

CLICK PHOTO

FOR SERIES III

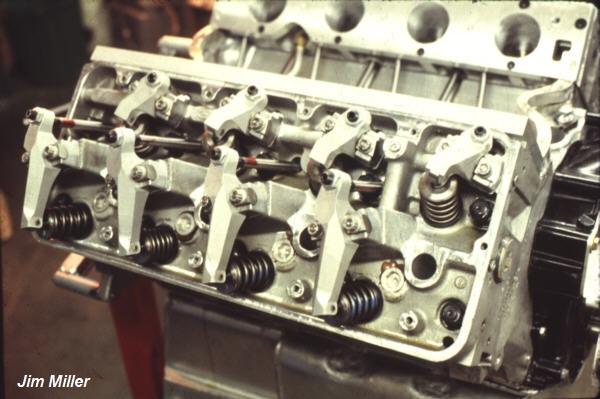

The

1977 Series II BOSS rockers were machined from solid 7075-T6 Billet

Aluminum and fitted with Torrington needle bearings. Specially made

shafts that copied the NASCAR design, but incorporated a 5/8" diameter

were used in lieu to the .700" NASCAR dimension. Original NASCAR

stands were retained and modified to accommodate. Precision ground

steel plates nearly 1/4" thick were made to elevate the rocker as

needed to establish MID-LIFT geometry, first developed on the Series I

model in 1973.

Little

emphasis on pretty, shiny anodized surfaces was used, but they were

light, strong and safely allowed the engine up to 9,300 rpm, an

unheard of value for a big block in 1977. Repeat NHRA World Champion

Bob Glidden contracted several sets in 1979 when he switched from the

351 to a destroked BOSS 429.

|

|

|

Lee Farrell's Ford Truck Pull engine (ca 1981); America's 1st Aftermarket

Aluminum BOSS block. |

|

|

By 1980 or

'81, Jesel came out with his straight beam version of a rocker for the

BOSS engine and used the same bottom side ball mill lightening copied from

Miller. His early pieces added a second ball mill plunge on the back side

of the shaft bore, which proved fatal. That step was dropped.

|

|

The JESEL exhaust rocker for the BOSS

429, is rotated from the Ford mounting pad to "straighten up" Ford's deliberate

rotation and compound geometry, which balanced side thrusts back and forth

during the opening and closing cycle. JESEL'S change required welding and

machining, using quaint little steel blocks with dowel pins that serve as a jig,

but were (and are) very inaccurate as designed to be used. The process destroyed

the OEM mounting, making going back nearly impossible, or at least impractical.

What no one seemed to understand was the result of such a change was a bias side

load placed entirely in one direction, making harmonic control in the very long

exhaust pushrod (nearly 11 inches) impossible as well. The Miller system

maintained the Ford rotation, understanding it wasn't simply "to fit" around the

ports. Unfortunately, JESEL's compromise got copied by well known engine

builders and head manufacturers trying to resurrect a vague semblance of this

great engine; and thus, the problems. JESEL's answer for an intake rocker was to

use his Big Block Chevrolet rocker, even though its design geometry isn't

even close. The BOSS engine is the most susceptible of any American OHV engine

to optimum valve train geometry, and when any compromises are made -- the

detriment is even greater.

|

MILLER MID-LIFT™

The Standard By Which All Is Measured!™

954-978-2171 MillerRockers@aol.com

MID-LIFT™, PRO-SHAFT™ & PRO-STUD™ are JM Miller Trademarks; Copyright © MMIII~MMXXIV

| |