|

SERIES III,

1983

|

|

|

|

CLICK PHOTO For SERIES

II

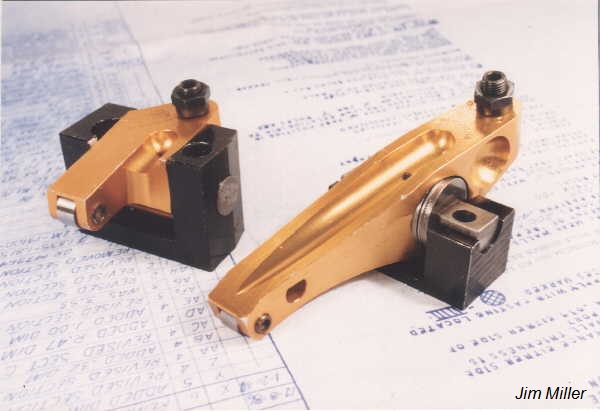

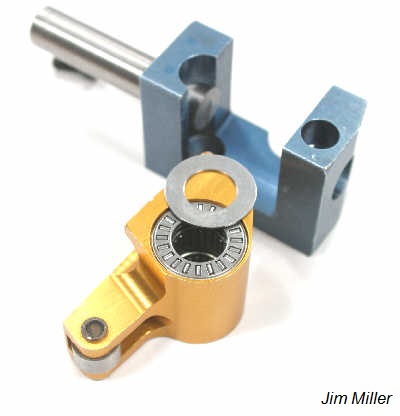

Miller

trademark needle thrust bearings were first used on the BOSS 429 Series

III rockers, and continued to the PRO-SHAFT NASCAR designs 12 years later.

Industry first on both.

|

CLICK PHOTO For SERIES

IV

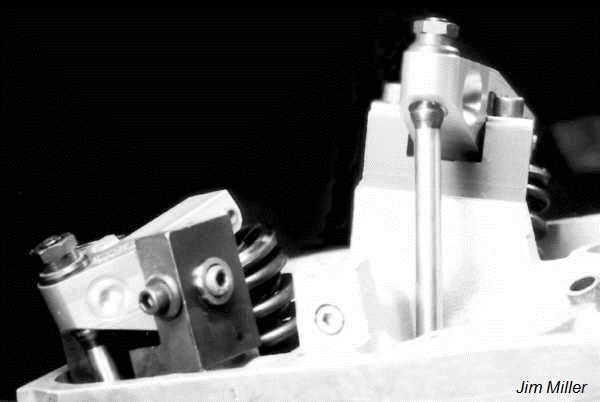

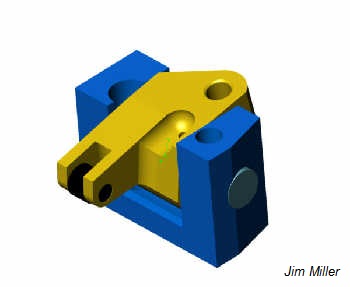

The Exhaust

Push-Rod leans away from the valve, while the Intake Push-Rod leans toward

the valve, forcing changes in height for geometry to require changing the

overall length of the rocker.

|

|

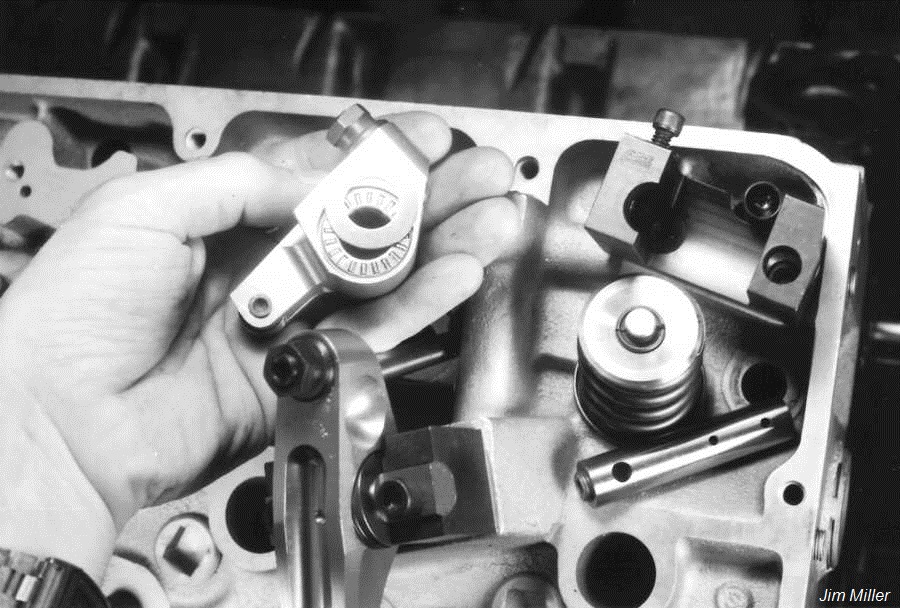

1983 marked the debut of the Series III

Miller MID-LIFT BOSS rockers, and perhaps the best. Although inherent BOSS

429 push-rod design geometry would remain the same, the Series III required

their own stands be designed to accommodate all new rocker bodies. The most

significant improvement was the straight line point-to-point Exhaust rocker,

which maintained the original Ford compound geometry necessary to controlling a

balanced division of side loads. Other manufacturers' designs

attempted to straighten this up by rotating the shaft and stand. The result was an excessive side

load in one direction only. Another first "drip down' oil holes placed at the

bottom of the ball mill lightening atop the rocker to feed the bearings; copied

later by other manufacturers. The Series III would often fit

beneath the OEM BOSS valve cover with only minimal work on the flange lip. Some

castings however, required a 1/2" spacer plate be added. |

|

|

|

PUSH-ROD SIDE-THRUST IS

EVIDENT |

|

|

|

INTAKE THRUST BEARINGS |

EXHAUST THRUST BEARINGS |

|

The GOSPEL of MID-LIFT geometry was

published in an article by Jim Miller that appeared in a Super Ford Magazine

in July, 1981, called:

To

Rock Or Not To Rock. That was 8 months after the Miller MID-LIFT

Patent was filed; 13 months before the Miller MID-LIFT Patent was issued. It

would be another 11

years before the Chevrolet Race Shop engineers endorsed it and duplicated the same information

in an October, 1992 issue of Car Craft Magazine, proclaiming these

principles as their official optimum rocker geometry. Seven years after that, on

March 9, 1999, Chrysler would mandate in a confidential engineering brochure

that ONLY MID-LIFT geometry be used for all seven of its NASCAR teams,

spearheaded by their point team leader, Ray Evernham. It would be 22 years after

this 1983 implementation on the BOSS 429, Series III rockers before the most

popular name brand rocker manufacturer would begin to use "thrust

bearings" on any rocker, where nearly every PRO series rocker Miller has

ever designed was patterned after the principles of side thrust control first

developed here, on this system. |

|

The new

intake stand design utilized the OEM internal oiling from the head by

actually stealing it from the OEM stand's opposite side mounting bolt and

connecting a long vertical oil hole up to feed a free floating shaft. The

goal was to offer both OEM internal and push-rod oiling with

Miller's "drip down" design, without making any changes to the

heads themselves. The goal was met.

|

|

|

|

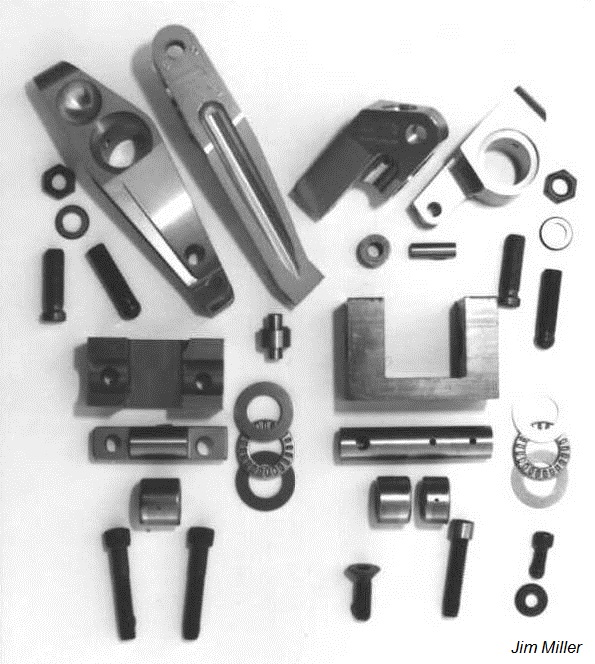

LEFT: Extra rocker bodies for two

perspectives are shown along with the remaining parts needed for one cylinder assembly.

Only 50

sets were made in 1983 and sold for $1,280 to $1,440. Today, they're like

GOLD, if you can find a set, and "if" you can convince the owner to sell

them. Won't happen. Wait for them to become part of the estate, then

fool the widow into selling them.

Some surface from time to

time, but most are still horded among BOSS owners, and not for sale.

Today's

2011 price to duplicate a set is factored at $5,600.

|

MILLER MID-LIFT™

The Standard By Which All Is Measured!™

954-978-2171 MillerRockers@aol.com

MID-LIFT™, PRO-SHAFT™ & PRO-STUD™ are JM Miller Trademarks; Copyright © MMIII~MMXXIV

| |